IBG HydroTech GmbH

Chain Rotor Nozzle 1"

Chain Rotor Nozzle 1"

SKU: 16 03 003

plus VAT and shipping costs

Regular price

€2.441,32 EUR

Regular price

Sale price

€2.441,32 EUR

Unit price

per

| 0 | 400 | |

| 50 | | 400 |

| 0 | |

300 |

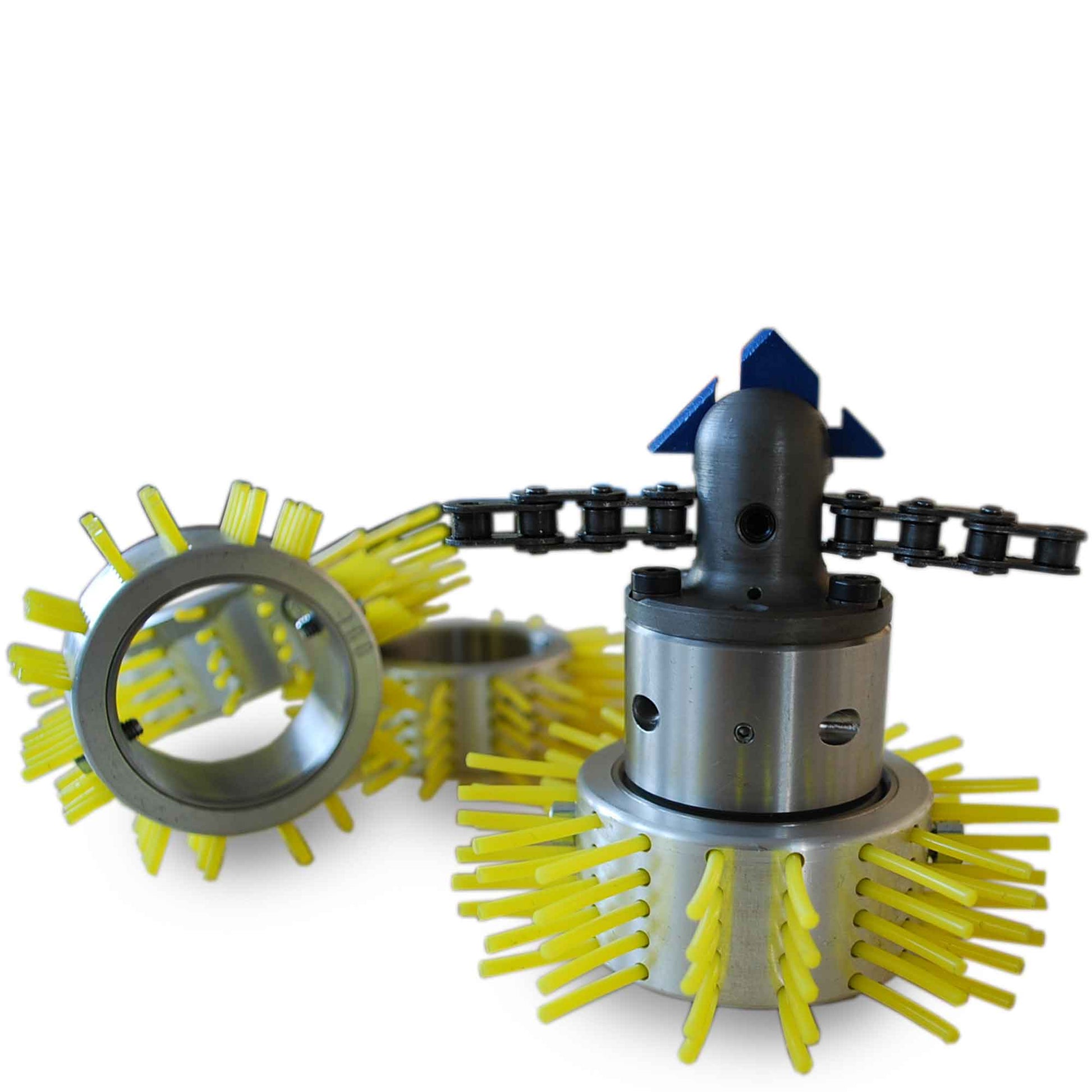

IBG produces the chain rotor nozzle in different variants and with different accessories.

The difference between the combination chain rotor and the standard chain rotor is that the combination chain rotor can be used with different types of chains, bicycle chains, link chains or milling wheels.

Standard chain rotors can only be used with link chains.

The recycled version has a powerful drive that can also be used with recycled water.

Set in carrying case: various brushes, chain set, tools, multifunction spray.

The difference between the combination chain rotor and the standard chain rotor is that the combination chain rotor can be used with different types of chains, bicycle chains, link chains or milling wheels.

Standard chain rotors can only be used with link chains.

The recycled version has a powerful drive that can also be used with recycled water.

Set in carrying case: various brushes, chain set, tools, multifunction spray.

⚙️ Connection thread

⚙️ Connection thread

1"

➡️ Front Jet

➡️ Front Jet

No

⬅️ Back Jet

⬅️ Back Jet

6 x M8 15°

🔄 Rotating nozzles

🔄 Rotating nozzles

4 x M8

🕳️ Fields of application

🕳️ Fields of application

Roots

📐 Dimensions and weight

📐 Dimensions and weight

L 165 / ø 70 mm and

♻️ Recycled water

♻️ Recycled water

No

💦 Volume flow

💦 Volume flow

200 -

📏 Suitable for DN

📏 Suitable for DN

125 - 200

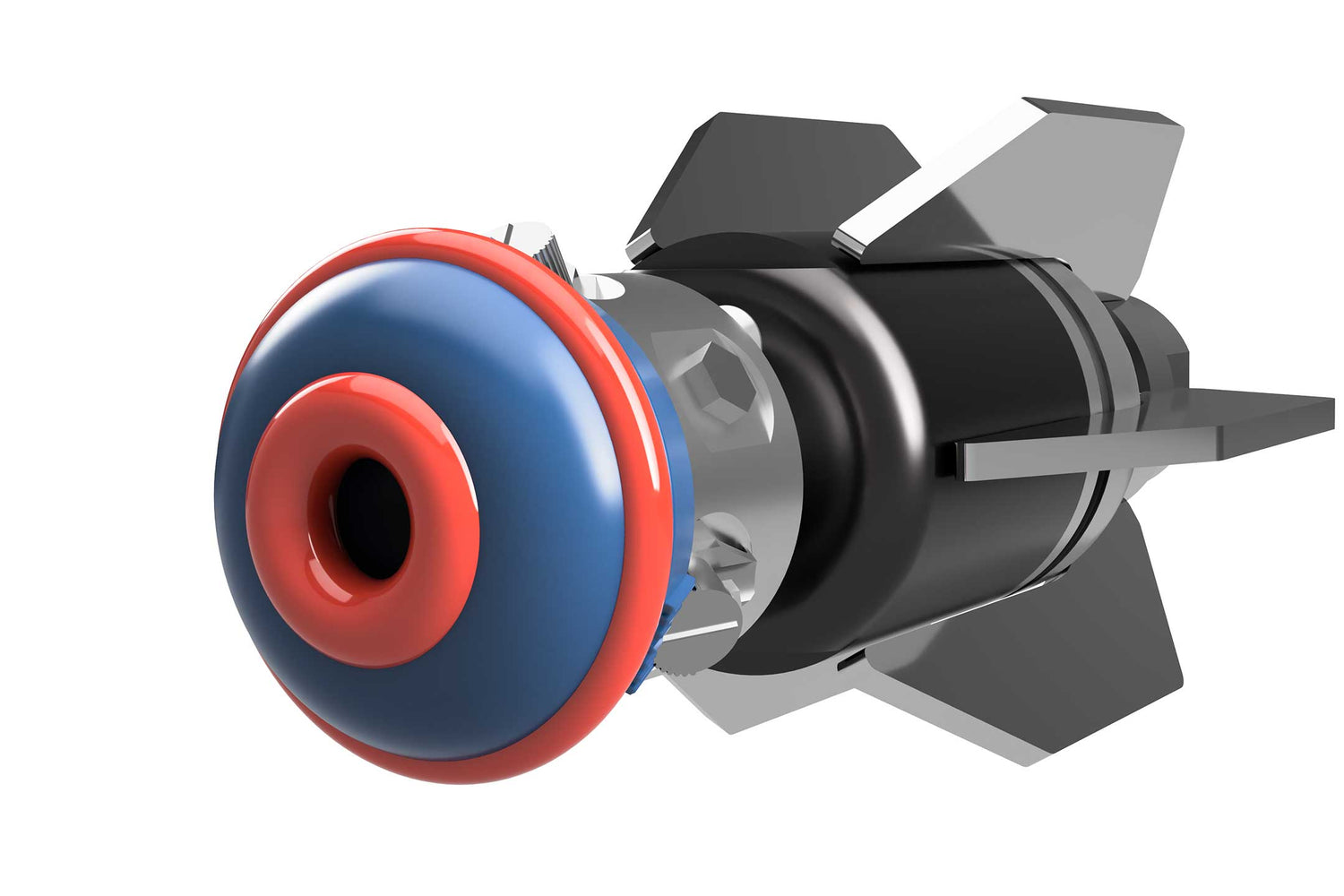

The new RotoMax 100

The RotoMax 100 was specially developed for use in industrial water.

The Rotomax is a universally applicable rotating sewer cleaning nozzle with easily and quickly exchangeable tool heads. The included wear-free brake ensures consistent, non-overriding milling characteristics. In addition, the bearings are protected, which ensures a long service life.

To RotoMax 100

The Rotomax is a universally applicable rotating sewer cleaning nozzle with easily and quickly exchangeable tool heads. The included wear-free brake ensures consistent, non-overriding milling characteristics. In addition, the bearings are protected, which ensures a long service life.