IBG HydroTech GmbH

Inversiondrums

Inversiondrums

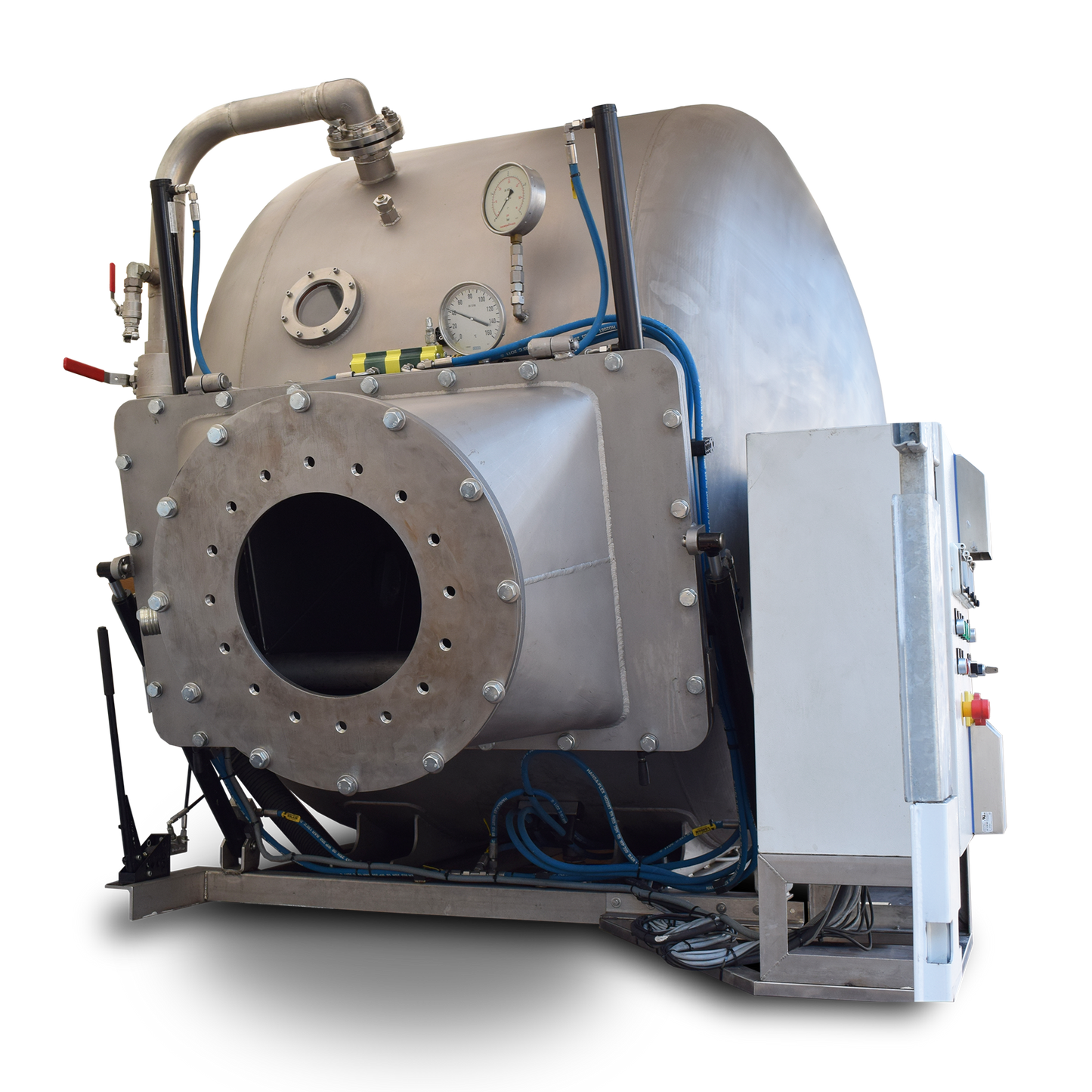

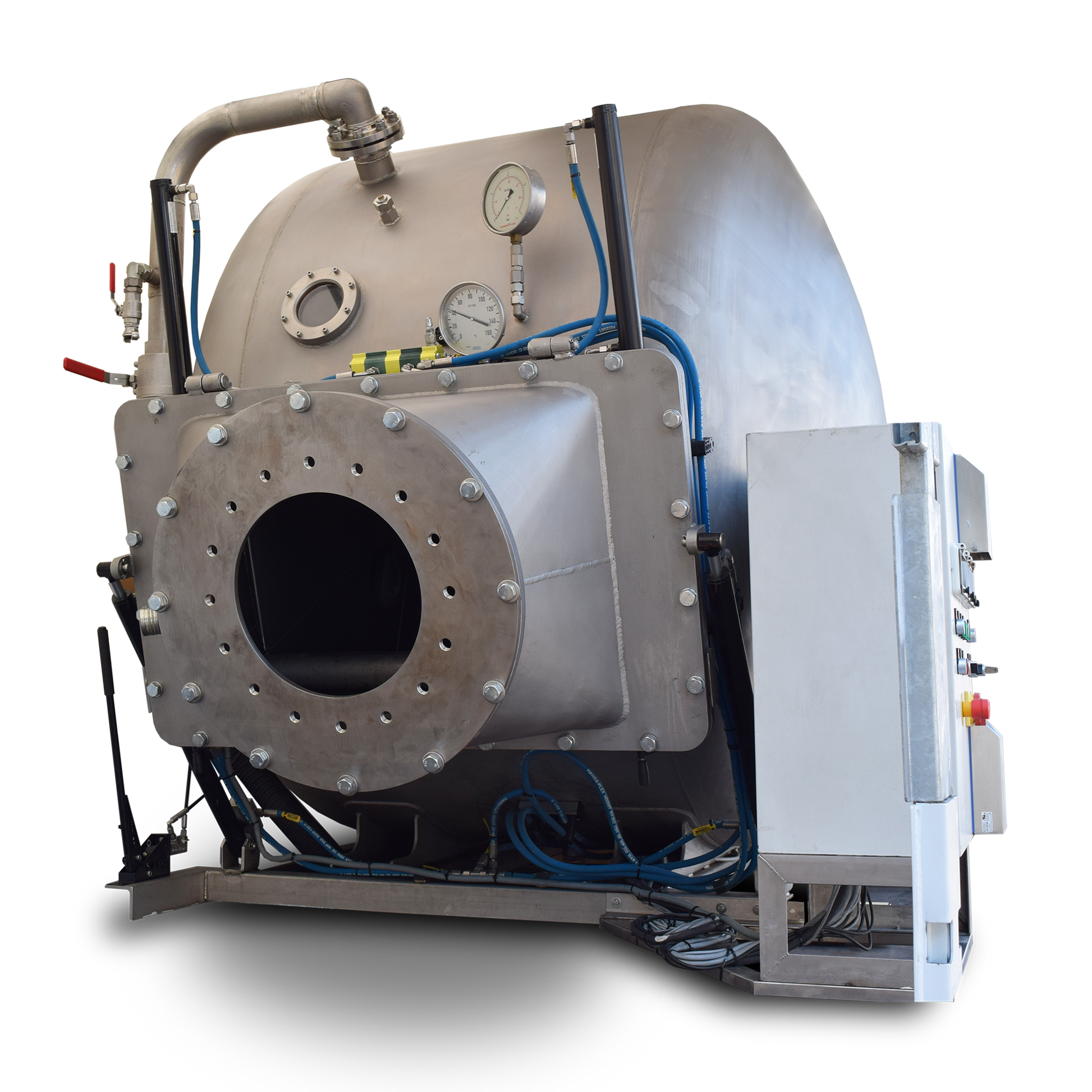

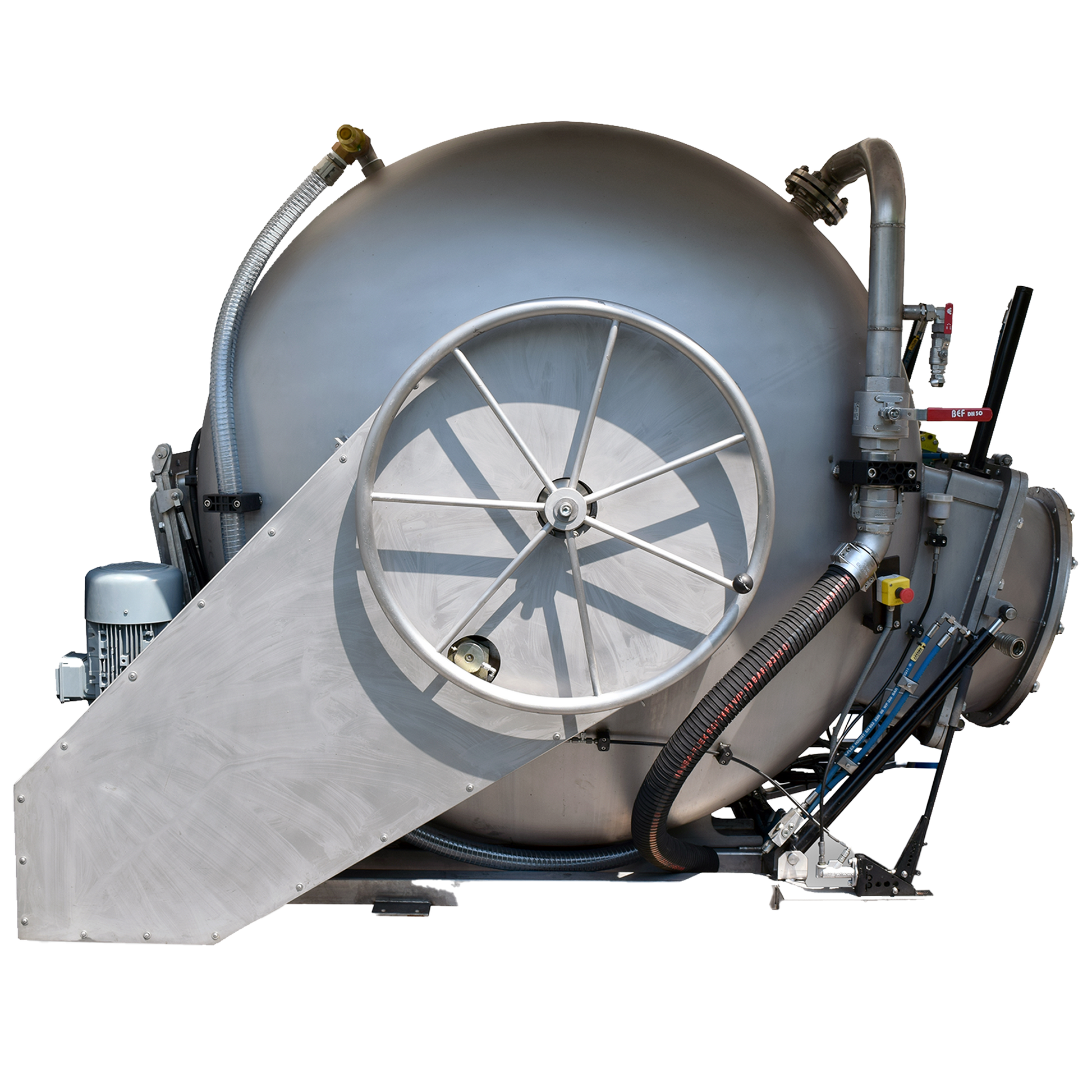

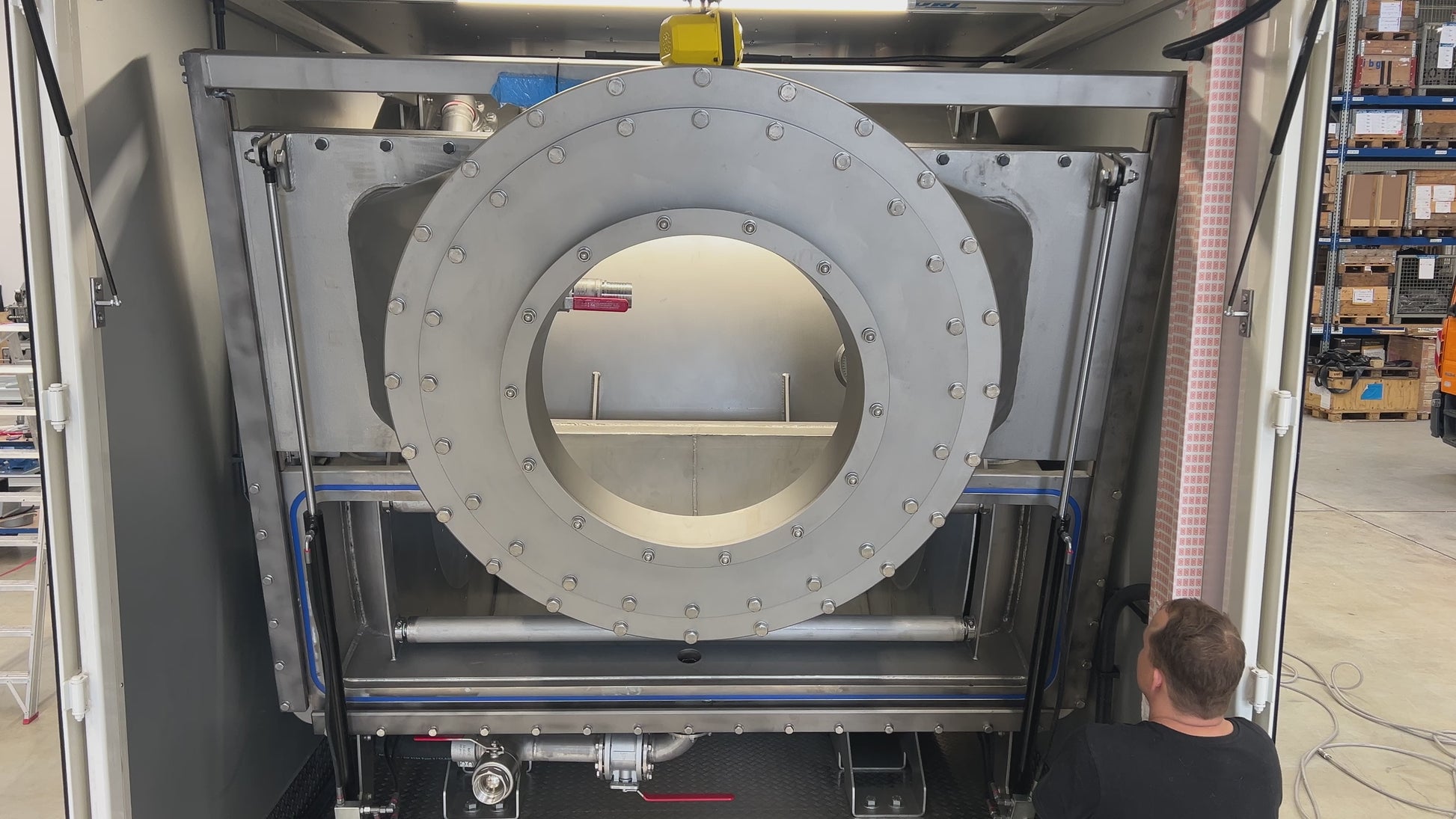

IBG Equipment for Inliner installation

With the help of an inversion drum a liner can be inserted easily into a deteriorated pipe. The coiled

liner is “inflated” using air pressure into the pipe section under repair. The liner is ‘inverted’, which means the resin impregnated fabric, originally on the inside, lays directly against the inner surface of the pipe and the coated inner surface now forms the inside of the pipe. By operating the rehabilitation pro- cess at the inversion drum, the inversion pressure and speed of advance through the pipe can be constantly controlled. After inserting the Inliner a heating medium (hot water or steam) is introduced into the liner via the drum causing the liner to ‘cure’. After the curing process a new pipe has been installed inside the old pipe.

IBG INV-Drum USP's

|

|

|

|

IBG inversion drums can be used for the rehabilitation of DN 100 – 2.000 mm / 4” to 80” pipes and are made entirely of stainless steel. They are according to customer requirement and challenges on the construction site. The models are therefore available in different sizes and designs. |

|

Technical Standard

Standard components

- State of the art & full stainless-steel design

- 10 years warranty on drum body

- 2 years warranty on the complete system

- More than 400 Inversion drums worldwide delivered.

- Compact design up to diameter 3,000 mm (10ft) for inliners up to DN 2,000 (80 inch)

- TÜV tested (pressure vessel)

- Hydraulic drive of the shaft with high speed

- Hydraulic quick closing of the loading flap (TÜV certified). Closing time approx. 30 seconds

- Pneumatic sealing of the flap ensures high reliability of sealing

- Electro-pneumatically controlled inlet and outlet valves (compressed air)

- Flange connection for water/steam supply

- Bottom drain with shut-off ball valve.

- Safety valve with guided media outlet

- Hydraulically moved closure flap with automatic locking device

- Liner limiting plates on the shaft that can be moved towards each other.

- Cable remote control with emergency stop

- Cone seal for inliner connection (100% sealing)

- Standard version suitable for operating temperature up to 130 °C (266 °F).

- Internal/external lighting

- Dynamic braking and holding system up to 2.5 bar (38 psi) inversion pressure

Optional

- Radio remote control and camera monitoring of the interior

- Assembly crane from DN 600

- Swivel system device +-90° for the INV drum.

- Lubricant spraying unit

- Chiller unit

- Display of inversion length

- Version up to 5 bar (75 psi) operating pressure

- Version up to 180°C (356°F) operating temperature

Technical data IBG Inversiondrum DNV > D2000

pls. note: 1 bar = 14,5 psi

TYPE DNIn ft |

TYPE DNIn mm |

Max DN InlinerIn inch-mm |

Standard working pressure |

Power consumption400 V KW |

Hydraulic automatic locking device |

Stainless Steel material |

TÜV certified |

Inliner Cone Fixing |

|---|---|---|---|---|---|---|---|---|

| 6,5 | 2000 | 32 - 800 | 1,5 or 2,5 | 8,5 | ✅ | ✅ | ✅ | ✅ |

| 8 | 2400 | 48 - 1200 | 1,5 or 2,5 | 8,5 | ✅ | ✅ | ✅ | ✅ |

| 8,5 | 2600 | 48 - 1200 | 1,5 or 2,5 | 10,5 | ✅ | ✅ | ✅ | ✅ |

| 10 | 3000 | 48 - 1200 | 1,5 or 2,5 | 12 | ✅ | ✅ | ✅ | ✅ |

IBG Inversiondrum LF capacity(ft) & Expected Inliner weight

| Inversion drum Type | 1600 | 2000 | 2400 | 2600 | 3000 | |

|---|---|---|---|---|---|---|

| max Inliner diameter (inch) | 20 | 32 | 48 | 48 | 48 | |

|

||||||

| 5 | 525 | 866 | 1214 | 1463 | 1969 | |

| 6 | 459 | 725 | 1053 | 1257 | 1647 | |

| 7 | 387 | 636 | 925 | 1076 | 1440 | |

| 8 | 354 | 554 | 817 | 942 | 1280 | |

| 10 | 285 | 453 | 650 | 774 | 1027 | |

| 12 | 236 | 387 | 541 | 640 | 863 | |

| 14 | 207 | 325 | 479 | 554 | 751 | |

| 16 | 177 | 295 | 404 | 479 | 646 | |

| 18 | 157 | 259 | 367 | 443 | 584 | |

| 20 | 135 | 236 | 325 | 400 | 541 | |

|

||||||

| Inversion drum Type | 1600 | 2000 | 2400 | 2600 | 3000 | |

|

20 | 32 | 48 | 48 | 48 | |

| Lbs. | ||||||

| 5 | 2178 | 8527 | 12346 | 14193 | 19506 | |

| 6 | 2394 | 8620 | 12496 | 14736 | 19584 | |

| 7 | 2438 | 8777 | 12875 | 14758 | 19676 | |

| 8 | 2562 | 8955 | 12888 | 14797 | 20183 | |

| 10 | 2588 | 8982 | 12782 | 15088 | 20474 | |

| 12 | 2560 | 9109 | 12679 | 14996 | 20512 | |

| 14 | 2421 | 9085 | 12608 | 15097 | 20750 | |

| 16 | 2368 | 9083 | 12540 | 15304 | 20816 | |

| 18 | 2326 | 9035 | 12452 | 15538 | 20860 | |

| 20 | 2297 | 9145 | 12399 | 15554 | 21182 | |